Language

The roll design and high-density ultra-fine fibers is better suited for automated equipment in environments with extremely high cleanliness requirements. Suitable for:

● Wafers, TFT, LCM (liquid crystal display modules), LCM port terminals, and the LED industry.

● Terminals of LCD modules, micro motor cleaning tapes, and the optoelectronics industry.

● Phone cover glass (CG), camera cover glass (CG), stainless steel sheets, digital printer heads, OCA full lamination, dispensing machine needles, assembled phone products, and optical fibers.

● Class 1000 to Class 100,000 cleanroom environments.

Request for Quote

WIPESTAR W5109 cleanroom wiper rolls are made from high-density microfiber (70% polyester + 30% nylon), suitable for environments with extremely high cleanliness requirements. The wipers are designed with perforated rolls setting up on machines for automated cleaning, and it is significantly reducing costs.

The fabric texture is soft and delicate with strong cleaning capability.

The four edges are heat-cut sealed with a fabric weight of 220 GSM.

● High-density ultra-fine fibers have extremely low particle release, making them suitable for environments with extremely high cleanliness requirements. Specially effective in removing particles smaller than 0.5µm.

● Silicone-free, low dust generation, low ion content, and low NVR, suitable for critical environment wiping.

● The soft and delicate fabric texture is ideal for wiping scratch-prone surfaces such as optical lenses, with minimal lint and residue.

● Heat-cut sealed edges reduce linting, ensure strong dust control at the edges, and prevent the edges from scratching surfaces, ensuring high cleanliness.

● Produced in a Class 1000 cleanroom and laundered with ultra-pure water.

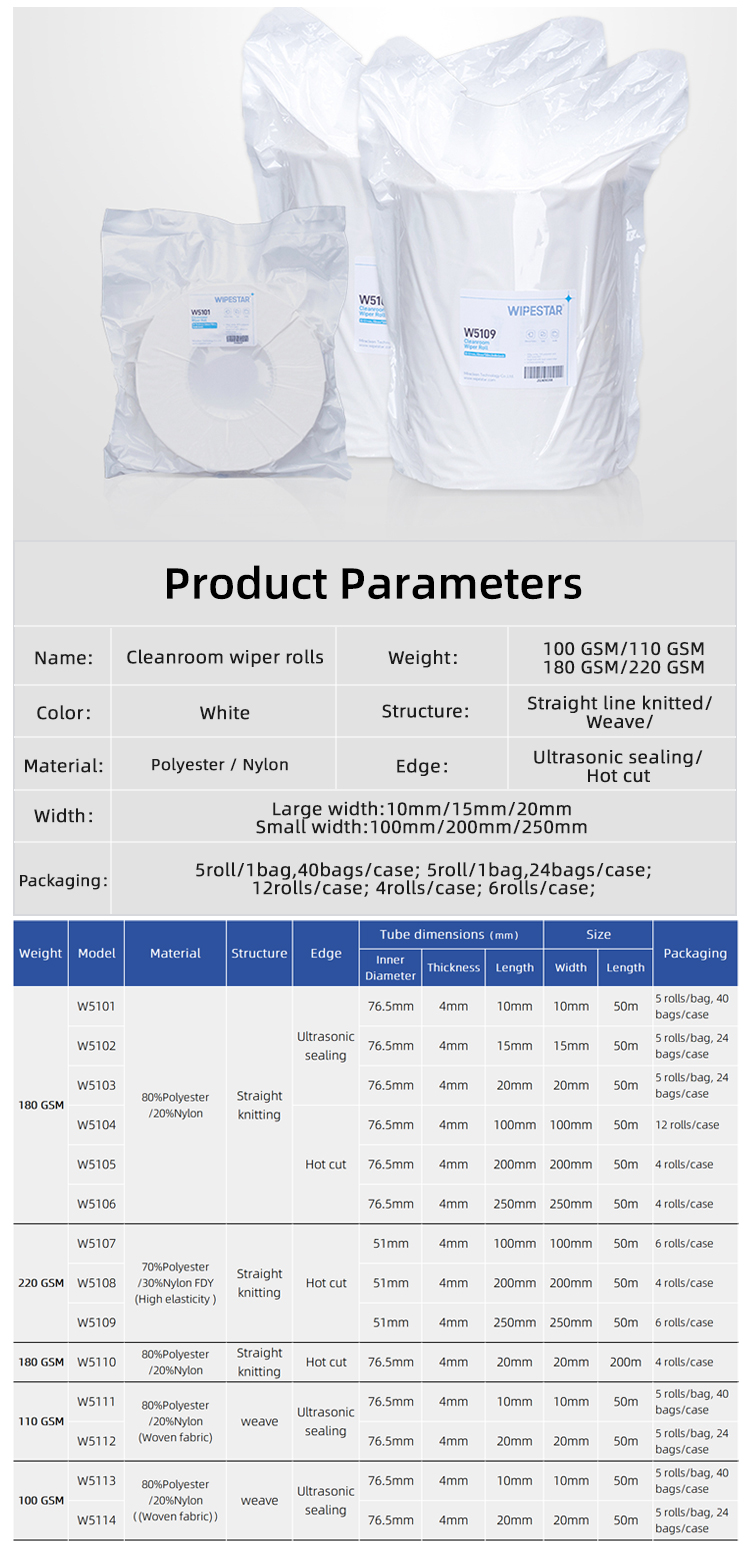

| Model | Weight | Material | Size | Pattern | Structure | Color | Packaging | Edge | Shipping |

| W5109 | 220 GSM | 70%Polyester/30%Nylon | Cloth size: 250mm x 50m Tube inner diameter: 51mm Tube thickness: 4mm Tube length: 250mm |

Plain | Single knitting | White | Perforated roll | Heat cut | 6 rolls/case |

Model

Weight

Material

Size

Pattern

Structure

Color

Packaging

Edge

Shipping

Request a Sample

Related Products

RELATED RESOURCES

Sub-fine Cleanroom Wipes: How Ultrafine Fibers Improve Semiconductor Cleaning Efficiency by 97.6%

Asia Dirtless Cloth: Cleaning Innovation Solutions in the Field of Precision ManufacturingBreakthrough in mate.........

More

Anti-static Dust-free Cloth Selection Technology: A Guide

Read this post to know what the anti-static dust-free cloth selection technology is to help you know how to pi.........

More

Laboratory-grade gentle protection: Baby products' laboratory baby wipes are changing the way mother

Why do obstetric nurses and new mothers quietly stock up on this "non-daily product"?In the neonatal.........

More

Chlorine bleach wipes in the drug research laboratory: the key force in improving cleanliness standa

Chlorine bleach wipes for drug research laboratories: the key force to improve cleanliness standards and prote.........

More

Laboratory Alcohol Wipes: Ideal for Disinfectant Cleaning

Laboratory alcohol wipes: "Invisible champion" of scientific cleaning and protectionIn industries wi.........

More

How do Dessert Lab Wipes revolutionize baking cleaning? An in-depth analysis of the three core techn

Deep interpretation of dessert laboratory wipes: innovative solutions for food safety and cleaningDefinition a.........

More

Related Products

RELATED RESOURCES

Sub-fine Cleanroom Wipes: How Ultrafine Fibers Improve Semiconductor Cleaning Efficiency by 97.6%

Asia Dirtless Cloth: Cleaning Innovation Solutions in the Field of Precision ManufacturingBreakthrou.........

More

Anti-static Dust-free Cloth Selection Technology: A Guide

Read this post to know what the anti-static dust-free cloth selection technology is to help you know.........

More

OEM Service

Timely Delivery

A-Grade Quality

Negotiable Pricing

CONTACT US

Complete the form, and a WIPESTAR Sales Consultant will contact you within 2 business days to help you get started.

WIPESTAR

微信官方公众号