Language

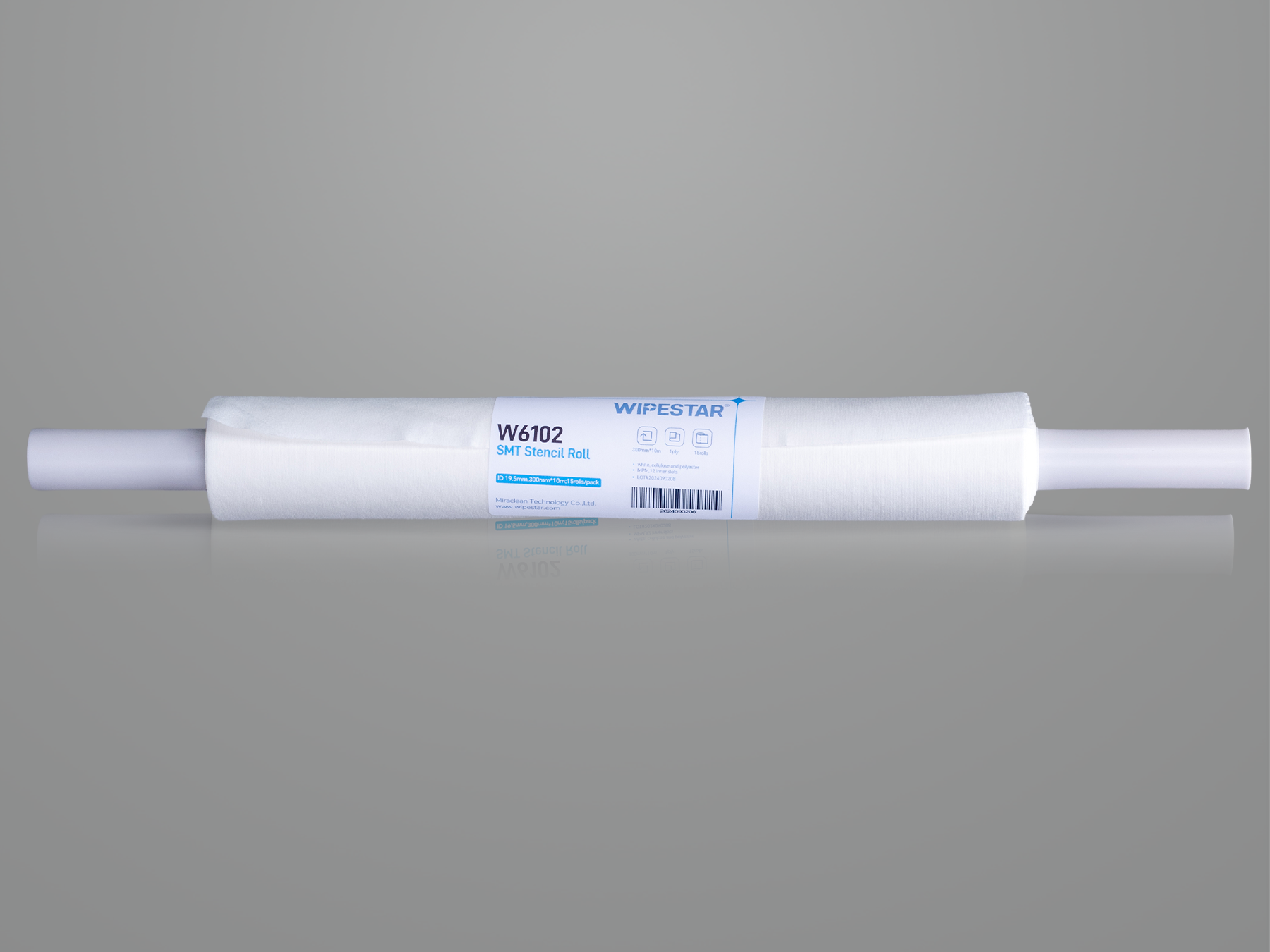

In the electronics manufacturing industry, print quality directly impacts product performance and reliability. As a leading supplier of cleaning rolls for MPM screen printers, we understand how every detail matters in your production process. Our Wipestar stencil rolls, crafted from premium CP fabric, represent a breakthrough in cleaning technology specifically engineered for MPM screen printers.

Our advanced hydroentangled material combines precisely balanced cellulose and polyester fibers to effectively remove residual adhesives, solder pastes, and fluxes. Whether used with or without solvents, these rolls maintain consistent cleaning performance throughout their service life. Meeting Class 100 Cleanroom standards with extremely low particle generation, our products fully comply with the stringent requirements of electronic manufacturing environments.

Understanding that different manufacturers have unique production requirements, we offer our stencil rolls in a range of widths from 250mm to 400mm, ensuring perfect compatibility with various MPM printer models. Each roll undergoes rigorous quality control to deliver superior absorption and optimal strength, effectively preventing common printing defects such as bridging and solder balls that can compromise your product quality.

In today's competitive electronics manufacturing landscape, both production efficiency and quality control are paramount. Our products feature excellent airflow characteristics that ensure optimal performance of vacuum cleaning systems. The durable construction resists tearing during use, reducing replacement frequency and helping control production costs. Additionally, built-in ESD properties make these rolls safe for use in sensitive electronic component manufacturing environments.

As your trusted partner, we go beyond simply providing superior products. We believe in building lasting relationships with our customers, backed by our technical expertise and commitment to your success. Our technical team stands ready to provide professional support, helping you optimize your production processes and improve yield rates. When you choose to work with us, you're selecting a partner dedicated to advancing your manufacturing excellence. Let's work together to create better outcomes for your production needs.

| Model | W6101 | W6102 | W6103 | W6104 | W6105 |

| Base Weight | 56g | 56g | 56g | 56g | 56g |

| Color | White | White | White | White | White |

| Fabric Material | 55% Wood Pulp 45% Polyester | 55% Wood Pulp 45% Polyester | 55% Wood Pulp 45% Polyester | 55% Wood Pulp 45% Polyester | 55% Wood Pulp 45% Polyester |

| Edge Sealing | Cold Cut | Cold Cut | Cold Cut | Cold Cut | Cold Cut |

| Core ID | 19.5mm | 19.5mm | 19.5mm | 19.5mm | 19.5mm |

| Core Thickness | 1.5mm | 1.5mm | 1.5mm | 1.5mm | 1.5mm |

| Core Length | 455mm | 455mm | 455mm | 455mm | 455mm |

| Core End Type | No Notch | No Notch | No Notch | No Notch | No Notch |

| Internal Ribs | 12 | 12 | 12 | 12 | 12 |

| Roll Width | 250mm | 300mm | 330mm | 350mm | 400mm |

| Roll Length | 10m | 10m | 10m | 10m | 10m |

| Packaging | 15 rolls/box | 15 rolls/box | 15 rolls/box | 15 rolls/box | 15 rolls/box |

| Application | MPM Printers | MPM Printers | MPM Printers | MPM Printers | MPM Printers |

| Cleanroom Grade | Class 100 | Class 100 | Class 100 | Class 100 | Class 100 |

| ESD Properties | Yes | Yes | Yes | Yes | Yes |

| Particle Generation | Very Low | Very Low | Very Low | Very Low | Very Low |

| Lint Level | Very Low | Very Low | Very Low | Very Low | Very Low |

| Tensile Strength | High | High | High | High | High |

| Vacuum Compatibility | Compatible | Compatible | Compatible | Compatible | Compatible |

RELATED RESOURCES

Laboratory-grade gentle protection: Baby products' laboratory baby wipes are changing the way mother

Why do obstetric nurses and new mothers quietly stock up on this "non-daily product"?In the neonatal......

More

Chlorine bleach wipes in the drug research laboratory: the key force in improving cleanliness standa

Chlorine bleach wipes for drug research laboratories: the key force to improve cleanliness standards and prote......

More

Laboratory Alcohol Wipes: Ideal for Disinfectant Cleaning

Laboratory alcohol wipes: "Invisible champion" of scientific cleaning and protectionIn industries wi......

More

How do Dessert Lab Wipes revolutionize baking cleaning? An in-depth analysis of the three core techn

Deep interpretation of dessert laboratory wipes: innovative solutions for food safety and cleaningDefinition a......

More

Related Products

Room 101, Building 1, Angeer Factory, No.4, Hetian Road, Shatian Community, Kengzi Street, Pingshan District, Shenzhen, Guangdong, P.R. China 518122

info@wipestar.com

+86-755-89616775

+86-755-89616773

Related Products

RELATED RESOURCES

Laboratory-grade gentle protection: Baby products' laboratory baby wipes are changing the way mother

Why do obstetric nurses and new mothers quietly stock up on this "non-daily product"?In the neonatal.........

More

Chlorine bleach wipes in the drug research laboratory: the key force in improving cleanliness standa

Chlorine bleach wipes for drug research laboratories: the key force to improve cleanliness standards and prote.........

More

WIPESTAR

微信官方公众号