Language

Used for wiping and cleaning the stencil of DEK screen printers.

Notches: 2 at each end

Ribs: No

Material Weight: 56 g/m2

Material Width: 510mm

Material Length: 10m

Core ID: 20mm

Core Length: 530mm

Core Material: Plastic

Request for Quote

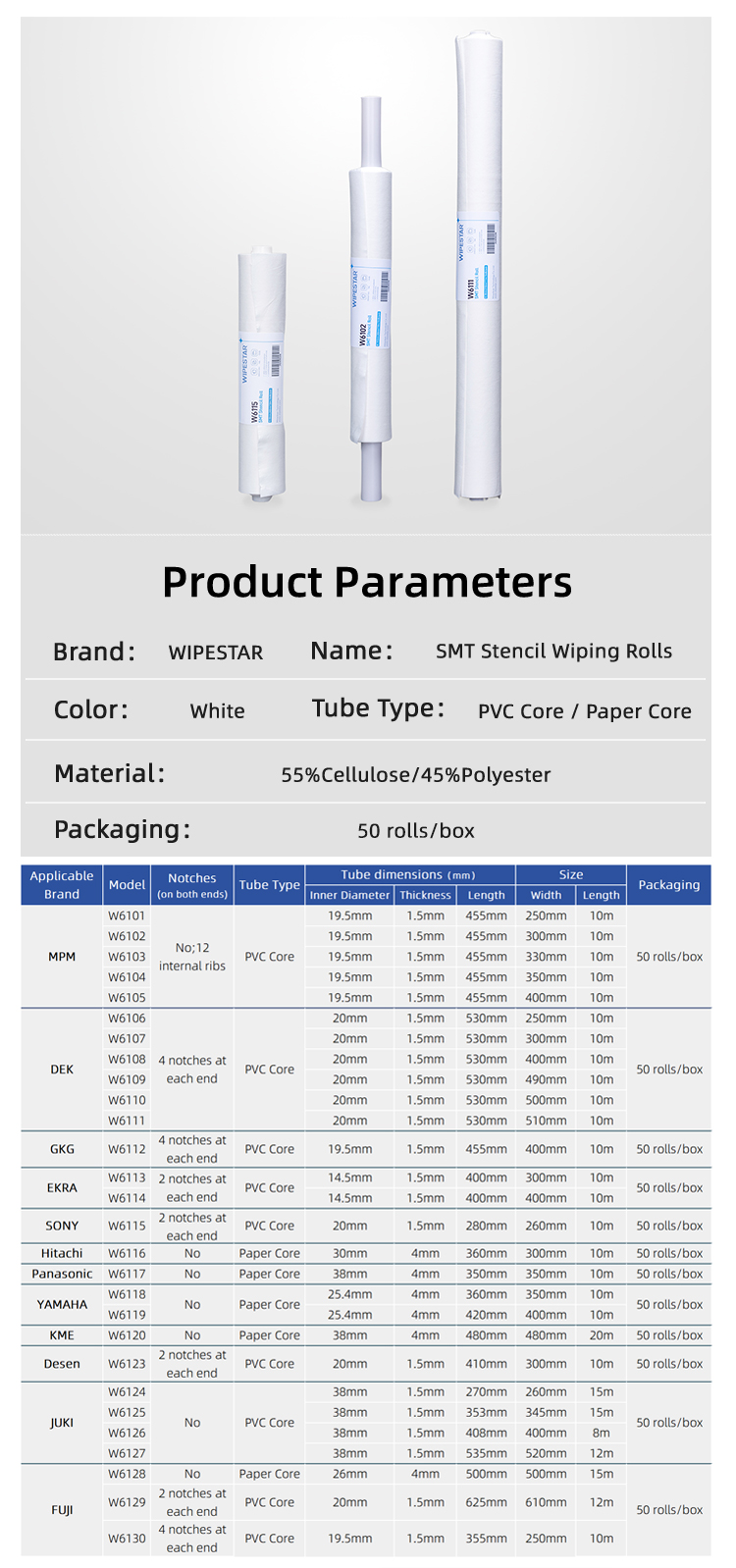

WIPESTAR's SMT printer cleaning series is perfectly compatible with various brands and models of printer stencil wiping needs. We choose materials for the wiping cloth that have low linting properties and leave minimal dust after wiping. They effectively clean surfaces, have high dry and wet strength, and can be used with solvents.

DEK Stencil Wiping Rolls with plastic cores have 2 notches at each end.

DEK Series Specifications (Core ID×Core Length×Material Width×Material Length):

Model W6106: Φ20mm×530mm×250mm×10m

Model W6107: Φ20mm×530mm×300mm×10m

Model W6108: Φ20mm×530mm×400mm×10m

Model W6109: Φ20mm×530mm×490mm×10m

Model W6110: Φ20mm×530mm×500mm×10m

Model W6111: Φ20mm×530mm×510mm×10m

● Unique Processing

Made from natural cellulose and high-quality materials, processed using a unique spunlace method, forming a distinctive 2-ply structure of cellulose and polyester.

● PVC Core Tube

The inner and outer walls of the core tube are smooth and even, easy to position, and do not loosen during cleaning. It has high impact strength and superior quality.

● Strong Absorption and Cleaning Power

The paper is smooth and leaves no traces on PCB board stains. It has high water and oil absorption capacity and excellent cleaning ability.

● Low Lint

Strong and durable, with extremely low dust and lint production.

| Model | Weight | Material | Size | Pattern | Structure | Color | Packaging | Edge | Shipping |

| W6111 | 56 GSM | 55%Cellulose/45%Polyester Core Material: Plastic |

Material Width: 510mm Material Length: 10m Core ID: 20mm Core Length: 530mm |

Plain | Spunlace | White | Perforated roll | Cold cut | 15 rolls/box |

Model

Weight

Material

Size

Pattern

Structure

Color

Packaging

Edge

Shipping

Request a Sample

Related Products

RELATED RESOURCES

Laboratory-grade gentle protection: Baby products' laboratory baby wipes are changing the way mother

Why do obstetric nurses and new mothers quietly stock up on this "non-daily product"?In the neonatal.........

More

Chlorine bleach wipes in the drug research laboratory: the key force in improving cleanliness standa

Chlorine bleach wipes for drug research laboratories: the key force to improve cleanliness standards and prote.........

More

Laboratory Alcohol Wipes: Ideal for Disinfectant Cleaning

Laboratory alcohol wipes: "Invisible champion" of scientific cleaning and protectionIn industries wi.........

More

How do Dessert Lab Wipes revolutionize baking cleaning? An in-depth analysis of the three core techn

Deep interpretation of dessert laboratory wipes: innovative solutions for food safety and cleaningDefinition a.........

More

Thermal Printer Cleaning Wipes: Industry Maintenance Solutions and Efficiency Improvement Practices

Analysis of the technical analysis of the thermal printer cleaning wipes: maintenance guide and industry appli.........

More

3D Printer Nozzle Wipes: A Complete Analysis of High-Temperature, Durable, and Precision Cleaning Te

3D printer nozzle wipe cloth: a key tool for maintaining the precision of equipment. As 3D printing technology.........

More

Related Products

RELATED RESOURCES

Laboratory-grade gentle protection: Baby products' laboratory baby wipes are changing the way mother

Why do obstetric nurses and new mothers quietly stock up on this "non-daily product"?In th.........

More

Chlorine bleach wipes in the drug research laboratory: the key force in improving cleanliness standa

Chlorine bleach wipes for drug research laboratories: the key force to improve cleanliness standards.........

More

OEM Service

Timely Delivery

A-Grade Quality

Negotiable Pricing

CONTACT US

Complete the form, and a WIPESTAR Sales Consultant will contact you within 2 business days to help you get started.

WIPESTAR

微信官方公众号